Precautions for the application of ETL certified AC light source module

In each industry, there are different test standards. In electrical and optoelectronic products, the ETL inspection mark indicates that it has been tested and meets the relevant industry standards. ETL inspection marks are widely used in optoelectronic products, and ETL certified AC light source modules are also one of them. With the development of economy, there are more and more related applications involving ETL certified AC light source modules. However, a little carelessness when applying ETL certified AC LED Light module source modules will cause problems. So what should we pay attention to?

At present, as LED display applications become more widely used, consumers usually ask manufacturers to help install them when purchasing LED displays. Therefore, LED display installation is a compulsory subject for LED technicians. Although for experienced technicians, LED display installation can be described as a familiar road, for some technicians who have just contacted LED displays for a short time, they tend to overlook some places when installing LED displays, which leads to unnecessary There was a problem.

1. The input method used by the ETL certified AC light source module is low voltage, so you must not directly input 220V, otherwise the entire module will be damaged, which will cause unnecessary losses.

2. When installing the ETL certified AC light source module, double-sided adhesive or woodworking adhesive is required to make the module card slot and the blister base plate firmly adhered. When using double-sided tape, glass glue must be added, otherwise the module will fall off under long-time outdoor sunlight. This is very important.

3. When installing ETL-certified AC light source modules in blister letters or boxes, try to use three-point and four-point lines, and try to make the whole letter or the box form a loop or multiple loops when connecting. , That is, connect the modules at the end of each stroke according to the positive and negative poles with the red and black power cords. When the power cord is connected to the cabinet, it must first be connected to the corresponding four or three groups of modules through a four-point line or a three-point line. After the power cord enters the box, a larger knot should be tied to prevent the power socket of the ETL certified AC light source module from being pulled off by the outside force.

4. Adjust the output voltage of the ETL certified AC light source module in advance according to the actual situation. When the module is in use, the voltage cannot be adjusted at will, otherwise it will cause an impact.

5. Install the ETL certified AC light source module without waterproofing. Pay attention to whether water enters. Moreover, the special LED switching power supply can only be moisture-proof, not waterproof, so waterproof measures must be taken when the power supply is external.

6. When installing the ETL certified AC LED Light module source module, do not use too much force, so as not to cause damage to the device and affect the overall effect.

7. ETL certified AC light source modules have positive and negative poles. When installing, pay attention to whether the positive and negative poles of the power port correspond to each other. If the positive and negative are opposite, the module will not emit light. But don't worry, the module will not be damaged if it is connected reversely, just connect it back to the normal direction.

8. The spacing of ETL certified AC light source modules can be adjusted according to the brightness requirements, and the distribution per square meter is generally controlled between 50 and 100 groups.

9. It is recommended that the number of power ports in series should not exceed 50 groups, otherwise the voltage attenuation of the end module will reduce the brightness of the ETL certified AC LED Light module source module. Although this phenomenon can be reduced by looping, it is not recommended to connect too many modules.

10. Generally, when connecting the ETL certified AC light source module, the wires are firmly inserted to avoid falling off in the future. In order to prevent the occurrence of falling off in the future, oil barbs are usually added to the seat design. If the connection is inconvenient, you can exit and reinsert.

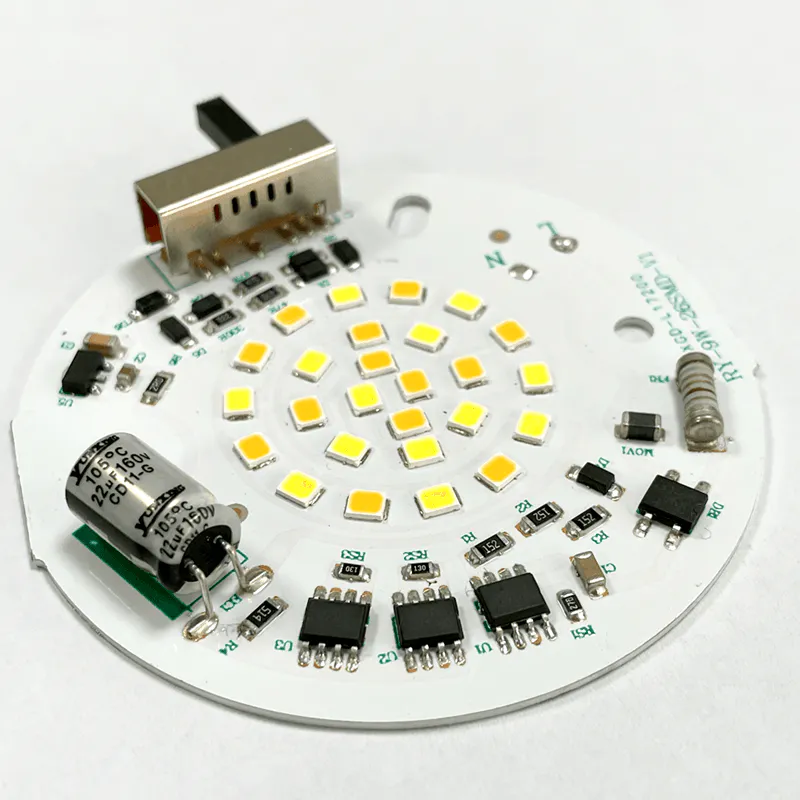

Demo Photoelectric Technology (Wuxi) Co., Ltd. who is highly knowledgeable about manufacturing as well as selling and confident in our ability to create finest products as About Us led light engine module.

Demo Photoelectric Technology (Wuxi) Co., Ltd. will continue to bring our industry nuances of style and approaches to About Us which are consistent with our evolving aspirations.

The rising dob led pcb consciousness observed worldwide are expected to be key factors driving the demand for led pcb module About Us.

The first step toward Demo’s successful selling campaign is to understand your customers. What are their needs or desires? Why would they support your product? Even more importantly, why would they be passionate about your product?

In a nutshell, is actually an ultimate solution for led pcb board and underestimating its value cost you higher than anything else. So grab it before you miss the boat.

Tel:

Tel: Email:

Email: