Large-scale outdoor display solution under ultra-low temperature conditions

The following Shenzhen Liansen Optoelectronics provides thermal insulation solutions for large outdoor display screens under ultra-low temperature conditions:

1. Using ultra-low temperature power supply: Japan TDK ultra-low power supply, Taiwan Mingwei ultra-low temperature power supply, Changzhou Chuanglian ultra-low temperature power supply, Shenzhen Xinxing ultra-low temperature power supply, etc. can achieve -40℃; -25℃ start. Among them, when the low temperature environment is close to the temperature limit of the power supply (for example, the ultra-low temperature is used at -35°C), the power load of the power supply will be derated, and the derating rate is close to 50%.

2. Installing a hot air curtain inside the LED display: make a closed channel inside the large screen, and install a hot air axial flow at the rear, and the working state of the hot air axial flow is realized by the temperature control system. When the temperature is lower than the set minimum ambient temperature, the hot air blower heats up, the screen temperature rises, and then the screen is turned on. When the temperature reaches the set temperature, the temperature control system cuts off the AC power supplying the hot air blower.

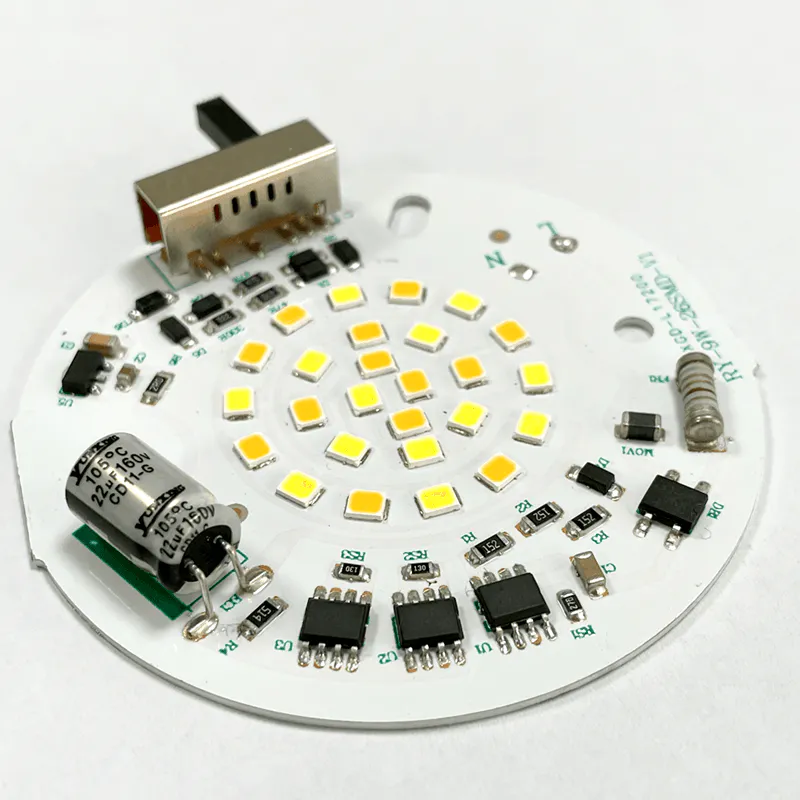

3. The 'three-proof' treatment of power supply and PCB circuit boards. Outdoor LED electronic displays are in the open air for a long time, so PCB circuit boards, power supplies, solder joints, etc. are required to be resistant to high and low temperatures, waterproof, fog, and corrosion. Our company conducts comprehensive 'three-proof' treatment on PCB circuit boards, components, and solder joints in outdoor electronic display systems. Circuit board three-proof paint is a specially formulated paint used to protect circuit boards and related equipment from Corrosion by the bad environment, thereby improving and prolonging their service life, ensuring the safety and reliability of use.

4. Use low temperature resistant sheet metal box.

Tel:

Tel: Email:

Email: