How to detect whether the LED unit board is damaged

1. Material

1. LED unit board sheet

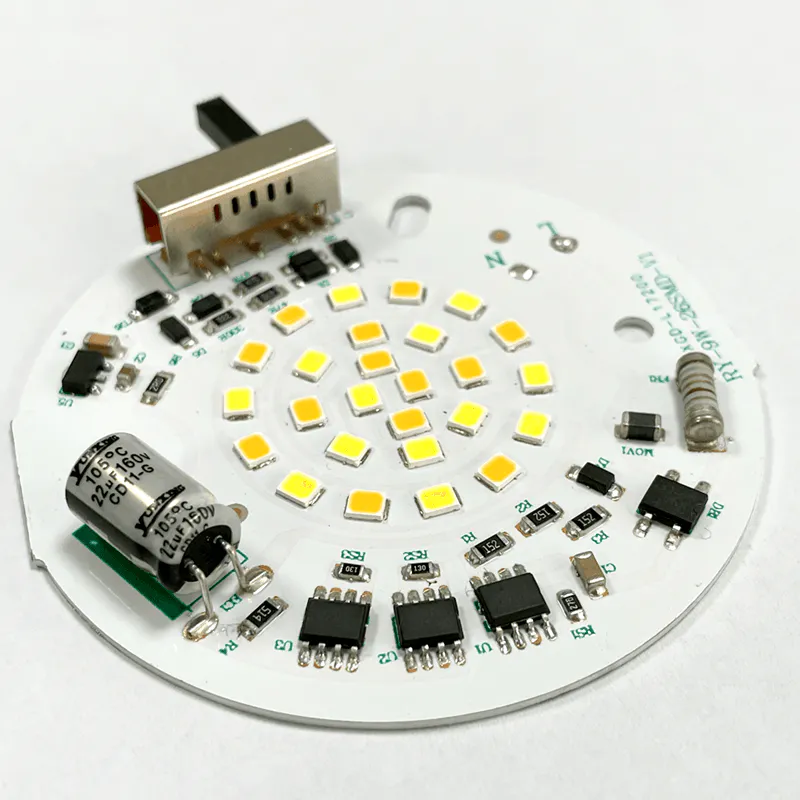

For low-cost competition, some LED unit board manufacturers use cheap flame-retardant paper boards or single-sided fiber boards as PCB circuit boards for LED lights. Because all glass fiber PCB boards are very expensive. At the beginning, no difference can be seen. Under normal circumstances, it will break due to moisture, ultraviolet damage, oxidation and other reasons within a year, resulting in the entire LED unit board being scrapped. High-quality LED unit boards must use double-sided full glass fiber PCB boards. Although the cost is high, the quality is guaranteed.

2. IC devices

Observe whether the brands of IC devices used are consistent. What type of IC is used, and how many ICs are used, these are enough to affect the quality of the LED unit board. Some LED display manufacturers, in order to save costs, will deliberately reduce the number of ICs or mix other brands of ICs when producing cell boards.

3. Lamp beads and chips:

The naked eye cannot distinguish the quality of the lamp beads. It can only rely on long-term testing, which is called the aging test by experts. The general practice of LED display manufacturers is: power on before leaving the factory to check whether the LED display can work normally, it will not undergo a long aging test. Because there are time costs and labor costs.

2. Welding quality

Check whether there is any missing or wrong placement of the component on the patch, and whether there is a short-circuit phenomenon of the component pin burr. Check whether the solder joints of the straight plug-in unit are smooth and round, whether the board surface is clean and tidy, and there is no missing solder. Check the flatness of the luminous dot matrix and the consistency of the ink color.

Three, power-on test

Power-on test (refer to the steps of 'Performance Test Report'):

①Electrically test the consistency of the luminous dot matrix;

② Power-on test whether the line drive tube CEM4953 is effectively protected;

③ Power-on test signal transmission capacity.

The above is about the common methods to detect the quality of LED unit boards, I hope it will be helpful to LED display vendors. In addition, quality is king, and manufacturers need to reject cheap and inferior LED displays, so as not to damage the unit board and affect normal work and subsequent unnecessary maintenance.

Demo Photoelectric Technology (Wuxi) Co., Ltd. is a company that offers a wide selection of . OEM and ODM services are also available to users. To know more, go to Demo Led Module.

Always do our research, follow the rules and plans ahead for additional expenses. Expanding is the goal of Demo Photoelectric Technology (Wuxi) Co., Ltd.; expanding properly is the goal of the wise business.

Lucky to know that you are not alone in the face of ac led modules issue. Let Demo Photoelectric Technology (Wuxi) Co., Ltd. be your selected About Us expert in providing first class to help you out.

Tel:

Tel: Email:

Email: