Daily maintenance instructions for outdoor LED display (module)

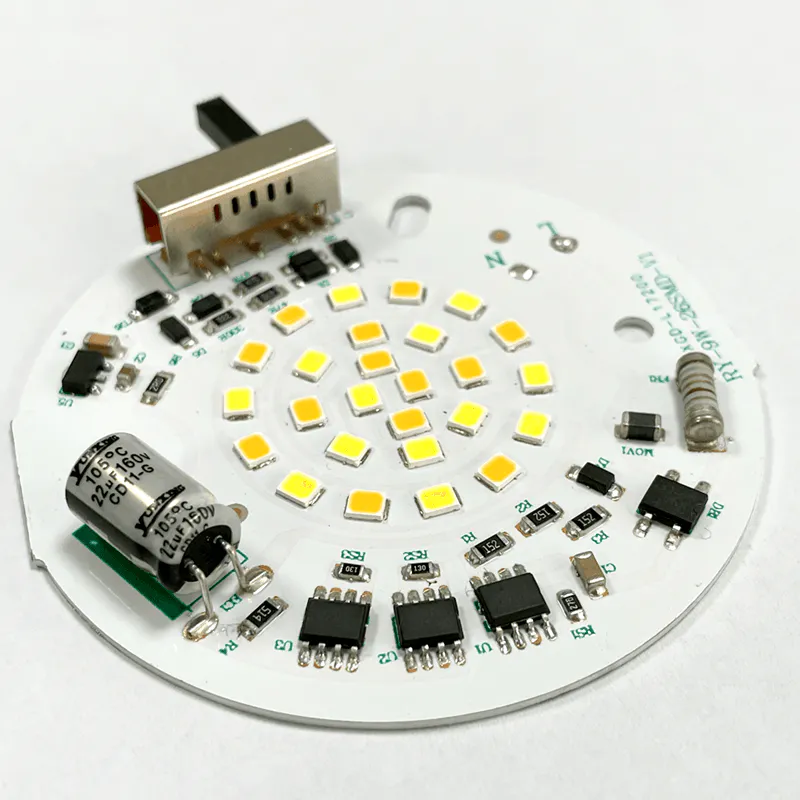

1. Multiple modules are not bright or abnormal: Check whether the cable and power cord of the first abnormal module in the signal direction are in good contact. If the module does not LED Light module up, it means there is no power input, please Check the power supply part (use a multimeter to check). If there is a pattern (with chaotic bright spots), it means that the module has no signal input. Please check whether the input terminal of the first abnormal module is in close contact and can be unplugged multiple times. Plug in the test, if there is a problem, you can still exchange a new flat cable.

2. Single module does not light up: check whether the power supply of the module is good, mainly check whether the power socket on the module is loose. If the color of the whole module is chaotic or inconsistent (but there is signal input, there is a correct picture), it means that the signal transmission line is poorly connected. Re-plug the flat cable, or replace the tested flat cable. If you still have the same problem after replacing a good flat cable, please check whether there is a problem with the PCB board interface.

3. Detection method for the problem of single LED Light module not bright: Use a multimeter to check whether the LED is damaged, if the light is broken, replace the light according to item 5 below. Specific lamp test method: set the multimeter to resistance X1, connect the black test lead of the analog multimeter to the positive electrode of the LED, and connect the red test lead to the negative electrode (the black pen of the digital meter is connected to the negative, and the red pen is connected to the positive). If the LED is on, the measured light is Yes, if the light is not on, the measured LED Light module is broken.

4. LED dead point maintenance (out of control point): After a single lamp is tested and confirmed as LED damage, the following maintenance methods can be selectively adopted according to actual needs.

Front maintenance: Use a screwdriver of the corresponding model to remove the screws of the fixed mask from the front (be careful to keep the screws), remove the mask, and replace the lamp (please change the lamp according to the following lamp replacement method), and the lamp replacement and gel seal are over After that, restore the original mask, tighten the screws (be careful not to press the lamp when you install the screws), and finally, if there is any glue remaining on the surface of the LED, please carefully remove the glue.

Back maintenance: Use a screwdriver of the corresponding model to remove the screws from the back (be careful to keep the screws), and unplug the signal cable. For safety, please do not unplug the power cable to prevent accidents. Take care to remove the module from the panel. Take it out of the gold hole, move it to the back of the box, and then perform maintenance and replacement of a single module according to the front maintenance method (please replace the lamp in the following lamp replacement method) or overhaul others.

5. Changing the lamp: Use a sharp tool (such as tweezers) to remove the colloid around the damaged LED, and make the LED pins clearly visible in the line of sight, use the tweezers to clamp the LED with your right hand, and use the soldering iron with your left hand (the temperature is about 40 Too high temperature will cause damage to the LED. Contact the solder and stay for a while (not more than 3 seconds. If it exceeds the time but does not meet the disassembly requirements, please cool down and try again) to melt the solder and use tweezers to The LED is removed. Correctly insert the LED lamp that meets the requirements into the hole of the PCB circuit board. (The long leg of the LED lamp is the positive pole, and the short leg is the negative pole. The 'square hole' on the PCB is the LED positive pin socket, and the 'round hole' is the LED pin. Negative pin jack), melt a little solder wire, glue it to the tip of the soldering iron, use tweezers to adjust the direction of the LED to make it stable, solder the solder to the connection between the LED and the PCB, use the same type of gel (PH value u003d 7) Seal the LED.

Demo Photoelectric Technology (Wuxi) Co., Ltd. helps high-profile clients build strategic relationships that drive company growth, investments, funding and more. There are many make-or-break details involved in the day-to-day manufacturing within our company.

If you would like to learn more about led pcb module About Us, and other types, please be sure to visit Demo Led Module. We can offer you top quality as well as cost saving price.

Demo Photoelectric Technology (Wuxi) Co., Ltd. has been focusing on reaching the ideal profits.

Tel:

Tel: Email:

Email: