Led full-color display assembly questions answer Daquan

01. What are the possible reasons for the failure to load?

The loading failure may be caused by the following reasons, please compare with your operation according to the listed items:

A. Make sure that the control system hardware is powered on correctly. (+5V)

B. Check and confirm that the serial cable used to connect to the controller is a straight-through cable, not a crossover cable.

C. Check and confirm that the serial port cable is intact and there is no looseness or fall off at both ends.

D. Select the correct product model, correct transmission method, correct serial port number, and correct baud rate by comparing the led display control software and the control card you choose, and check the dial switch diagram provided in the software to be correct Set the address bit and baud rate on the hardware of the control system.

E. Check if the jumper cap is loose or off; if the jumper cap is not loose, please make sure that the direction of the jumper cap is correct.

F. If it still fails to load after the above inspection and calibration, please use a multimeter to measure whether the serial port of the connected computer or control system hardware is damaged. To confirm whether it should be returned to the computer manufacturer or the control system Hardware return test.

02. What could be the cause of the communication failure?

The reasons for the communication failure and the loading failure are roughly the same. It may be caused by the following reasons. Please compare with your operation according to the listed items:

A. Ensure that the control system hardware has been powered on correctly. (+5V)

B. Check and confirm that the serial cable used to connect to the controller is a straight-through cable, not a crossover cable.

C. Check and confirm that the serial port cable is intact and there is no looseness or fall off at both ends.

D. Select the correct product model, correct transmission method, correct serial port number, and correct baud rate by comparing the led display control software and the control card you choose, and check the dial switch diagram provided in the software to be correct Set the address bit and baud rate on the hardware of the control system.

E. Check if the jumper cap is loose or off; if the jumper cap is not loose, please make sure that the direction of the jumper cap is correct.

F. If it still fails to load after the above inspection and calibration, please use a multimeter to measure whether the serial port of the connected computer or control system hardware is damaged. To confirm whether it should be returned to the computer manufacturer or the control system Hardware return test.

03. Why does the system prompt 'Please connect to the led display controller'?

Many customers and friends directly download the 'LED display control system' from the 'Download Center' on the company website. After running for 20 minutes after installation, the prompt 'Please connect to the led display controller' will appear. It is because the system did not detect the wide control system hardware within the test time. At this time, please connect one end of the led display control system hardware you purchased to the computer, and the other end to the HUB distribution board for HUB distribution The cable socket of the board is connected with the interface of each unit part of the led display screen.

After the connection is completed, you can enter the 'Settings' in the 'Settings' to set the relevant parameters, and then close and reopen the software. At this time, the word 'Connected successfully' will appear on the top of the software. At this time, the system The hardware of the display control system has been detected, and it can be used normally without time limit.

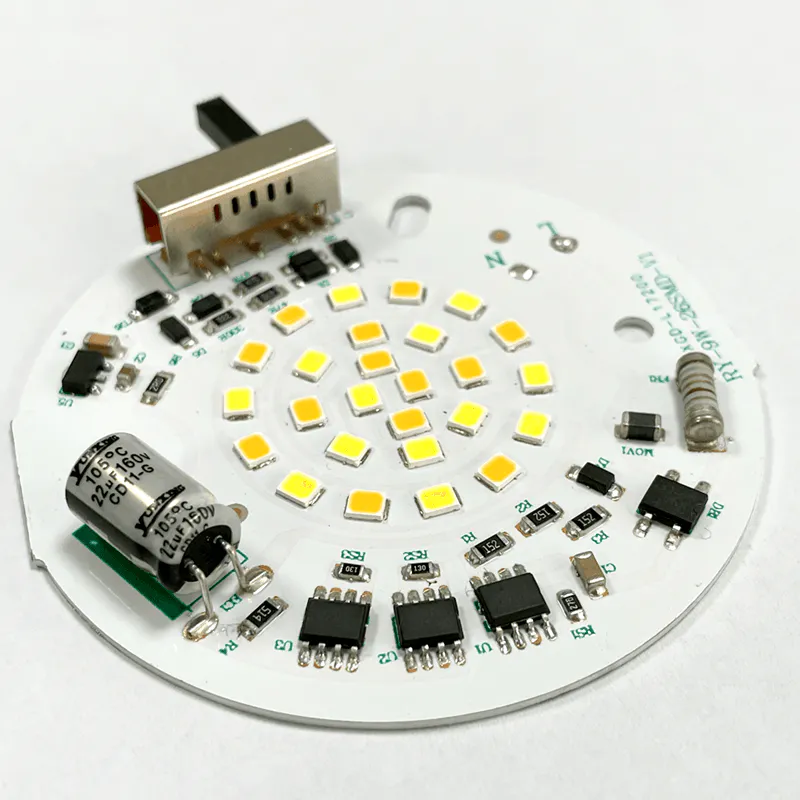

04. Why does the LED display control system hardware have a bright line or 'fuzzy screen' for a few seconds when it is first powered on?

After the display controller is properly connected to the computer and the HUB distribution board and the display, you need to provide +5V power to the controller to make it work normally (at this time, do not directly connect to 220V voltage). Power on In an instant, a bright line or 'fuzzy screen' will appear on the display for a few seconds. This bright line or 'fuzzy screen' is a normal test phenomenon, reminding the user that the display is about to start working normally. Within 2 seconds, this phenomenon will be automatically eliminated , The display enters the normal working state.

05. What does automatic or manual brightness adjustment mean?

Brightness adjustment refers to the adjustment made between the darkest and brightest that the display can display, not the sensitivity adjustment.

Automatic brightness adjustment is automatically adjusted to a predetermined brightness by the wide LED display control system according to the different brightness that should appear in different time periods.

Manual brightness adjustment means that the end user makes the LED display screen reach a certain specified brightness through the operation of the wide LED display control system.

Tel:

Tel: Email:

Email: